Steam heat exchangers specially designed by Erk Proses for industrial plants ensure efficient operation of steam systems. Optimized with high quality materials and engineering, these heat exchangers increase energy savings and system performance.

A steam heating exchanger is a device that allows hot steam to transfer its thermal energy to another fluid (such as water, oil, etc.) with lower thermal energy. As a result of this process, cooling steam exits the exchanger either in gas phase or condenses into liquid phase. It is then returned to the steam generator to be raised to the required steam quality for the process. The energy in steam form can be reused according to the demand in different parts of the process. A heating exchanger is used to increase energy efficiency and reduce energy costs. Moreover, it ensures efficient utilization of steam in steam power plants and other industrial plants.

A steam heating exchanger is a type of energy converter. A steam exchanger is a product that converts steam energy into water or other liquid. Steam is cooled by the steam heat exchanger, and its heat energy is transferred to water or another liquid. The steam heat exchanger ensures efficient utilization of steam energy and decrease in energy costs. Cooled and condensed steam can be sent back to the place where hot steam is generated and vaporized again.

A steam heating exchanger can be used in steam power plants, reverse osmosis plants, and other industrial applications. The exchanger ensures efficient utilization of steam energy and reduction in energy costs. Additionally, cooling of steam energy can help reduce the emission of harmful gases into the atmosphere.

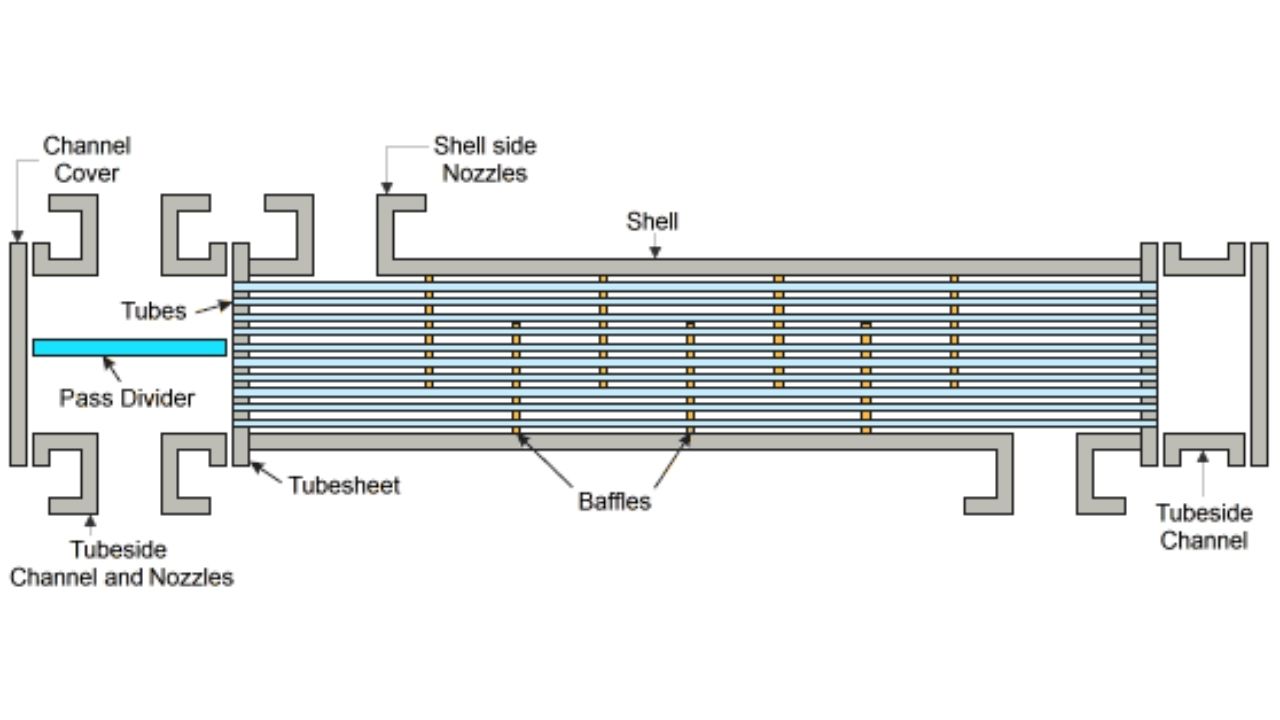

Steam heating exchangers can be produced with various designs. The materials used can vary depending on the application and requirements of the exchanger. These materials may include non-alloy steels, stainless steels, copper, and others that are suitable for fluid thermal and mechanical characteristics. Exchanger has a design consisting of a body, tubes, inlet and outlet ports, and supporting legs or columns.

For more detailed information about steam heat exchangers or to request a quote, you can contact us via the WhatsApp support line, our contact numbers, or by the quote request form available on our website.