Heat exchanger for heating, acquire heating by facilitating heat transfer between two fluids with different temperatures, ultimately heating the target fluid.

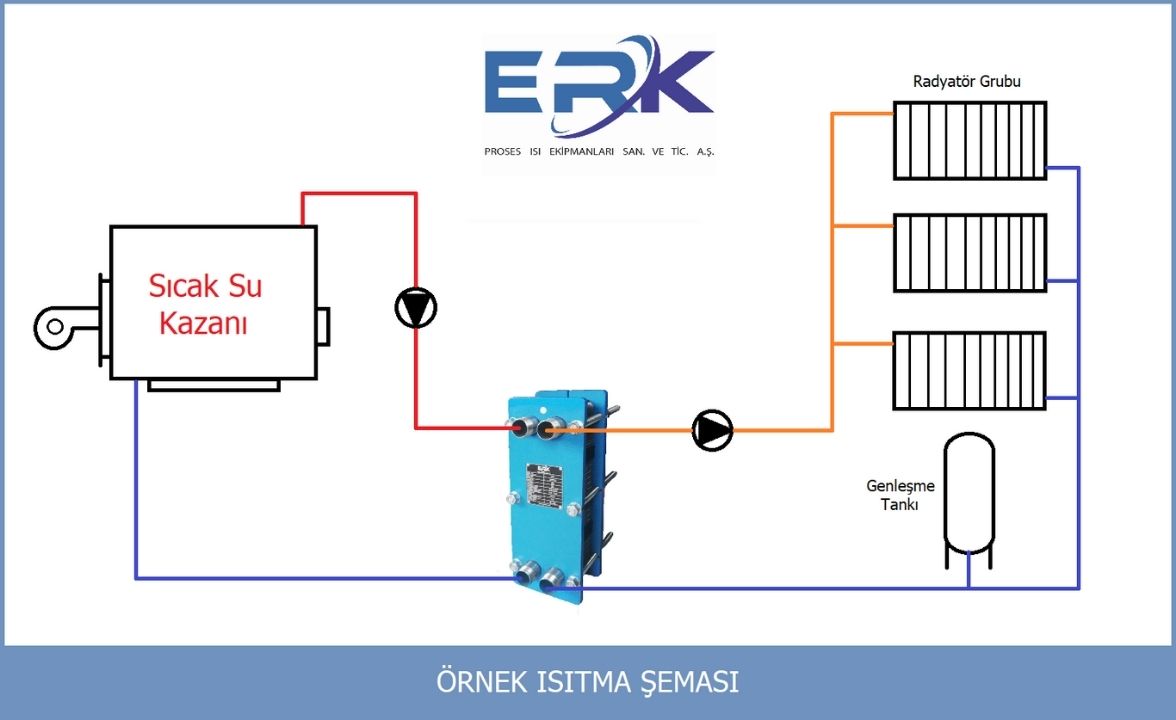

Heat exchangers for heating are equipment used to increase the temperature of a fluid. They acquire heating by facilitating heat transfer between two fluids with different temperatures, ultimately heating the target fluid. In these systems which operate on the basis of closed circuit, one fluid enters the exchanger from a heat source (boiler, heater, etc.). The target fluid, on the other hand, exits the exchanger by carrying out heat transfer through plates without mixing with the fluid coming from the closed loop heat source (for instance, building installation water, process fluid)

Heat exchangers for heating are used in various industrial processes, boiler systems, heating and cooling systems, and many other processes. They may come in different designs and sizes, but their fundamental purpose is to facilitate heat transfer and increase energy efficiency.

The design and sizing of heat exchangers for heating depend on factors such as fluid properties, flow rates, temperature differences, pressures, and other factors. These factors can influence the exchanger's heat transfer capacity, pressure loss, material selection, and energy efficiency. The necessary data for heat exchanger design is indicated in the table below. If these data is provided, ERK Proses offer you the most effective solution with appropriate pricing, according to technical suitability, for the desired heat exchanger.

| Primary Side | Secondary Side | |

| Fluid Name - Type | ||

| Inlet Temperature | ||

| Outlet Temperature | ||

| Flow Rate | ||

| Working Pressure | ||

| The Allowable Pressure Drop |

You can select the appropriate heat exchanger from the list below and create a request:

| Capacity | Model | Number of Plate | Pressure Category | Plate Material | Gasket Material | Price |

| 20.000 kcal/h | ERK-340ss | 25 | PN10 | AISI316 | EPDM | |

| 50.000 kcal/h | ERK-340ss | 35 | PN10 | AISI316 | EPDM | |

| 75.000 kcal/h | ERK-340ss | 45 | PN10 | AISI316 | EPDM | |

| 100.000 kcal/h | ERK-340ss | 60 | PN10 | AISI316 | EPDM | |

| 200.000 kcal/h | ERK-590ss | 45 | PN10 | AISI316 | EPDM | |

| 300.000 kcal/h | ERK-610ss | 35 | PN10 | AISI316 | EPDM | |

| 400.000 kcal/h | ERK-610ss | 45 | PN10 | AISI316 | EPDM | |

| 500.000 kcal/h | ERK-610ss | 55 | PN10 | AISI316 | EPDM | |

| 600.000 kcal/h | ERK-610ss | 65 | PN10 | AISI316 | EPDM | |

| 700.000 kcal/h | ERK-610ss | 75 | PN10 | AISI316 | EPDM | |

| 800.000 kcal/h | ERK-610ss | 85 | PN10 | AISI316 | EPDM | |

| 900.000 kcal/h | ERK-720ss | 60 | PN10 | AISI316 | EPDM | |

| 1.000.000 kcal/h | ERK-720ss | 65 | PN10 | AISI316 | EPDM |

Note: The heat exchangers listed in the table are valid for fluids with primary circuit inlet/outlet temperatures of 90-70˚C and secondary circuit inlet/outlet temperatures of 60-80˚C, as specified by the Ministry of Environment and Urbanization. For heat exchangers not listed in the table and tailored to your capacity requirements, please contact us for a selection that matches the specifications you requested.

For more detailed information about heat exchangers for heating or to request a quote, you can contact us via the WhatsApp support line, our contact numbers, or by the quote request form available on our website.