Special ship coolers designed by Erk Proses for the ship industry. ERK Proses is always with you with durable and efficient solutions.

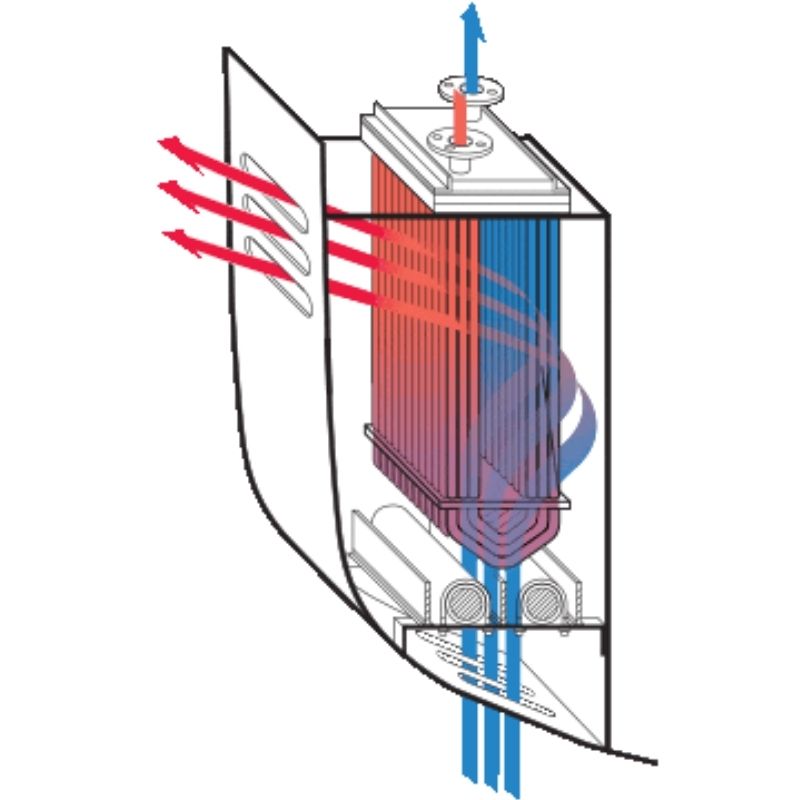

Box cooler is a type of water cooling system. Cooling process occurs on head section of the ship where U- tube bundle mounted in the sea chest located on the side of the ship and the inlet and outlet of the fluid to be cooled.

There are inlet and outlet grids on the sea chest to direct the flow of seawater. Seawater enters through the inlet grid and flows along the U-tube bundle until it reaches the outlet grid, thus cooling the coolant inside the tubes.

Cooling is acquired either through forced convection when the ship is in motion or through natural convection when it is stopped.

We provide services for box coolers with flexible design capacity, internal protection for the body, and anti-fouling systems to meet your specific needs. Upon request, the cooling pipes can be coated with a heat-setting synthetic coating that protects the unit from galvanic corrosion. This coating is also resistant to salty water, dirty water, floating debris, and chemicals. As a result, the service life of box coolers is significantly extended with the protection added. Additionally, to prevent marine- related fouling in box coolers, we further extend the service life with an ICAF (IMPRESSED CURRENT ANTI FOULING SYSTEM) system.

The tubes for box coolers can be designed to meet your requirements by ERK engineers specialized in material quality. Some commonly used pipe materials include aluminum brass alloy (CuZn20Al), cupronickel - cunife (CuNiFe), copper-nickel alloy (CuNi 90/10), and etc.

For more detailed information about box cooler or to request a quote, you can contact us via the WhatsApp support line, our contact numbers, or by the quote request form available on our website.