Effective kettle type heat exchangers specially designed by Erk Proses for industrial use. It provides confidence in your process with its high performance and long-lasting structures.

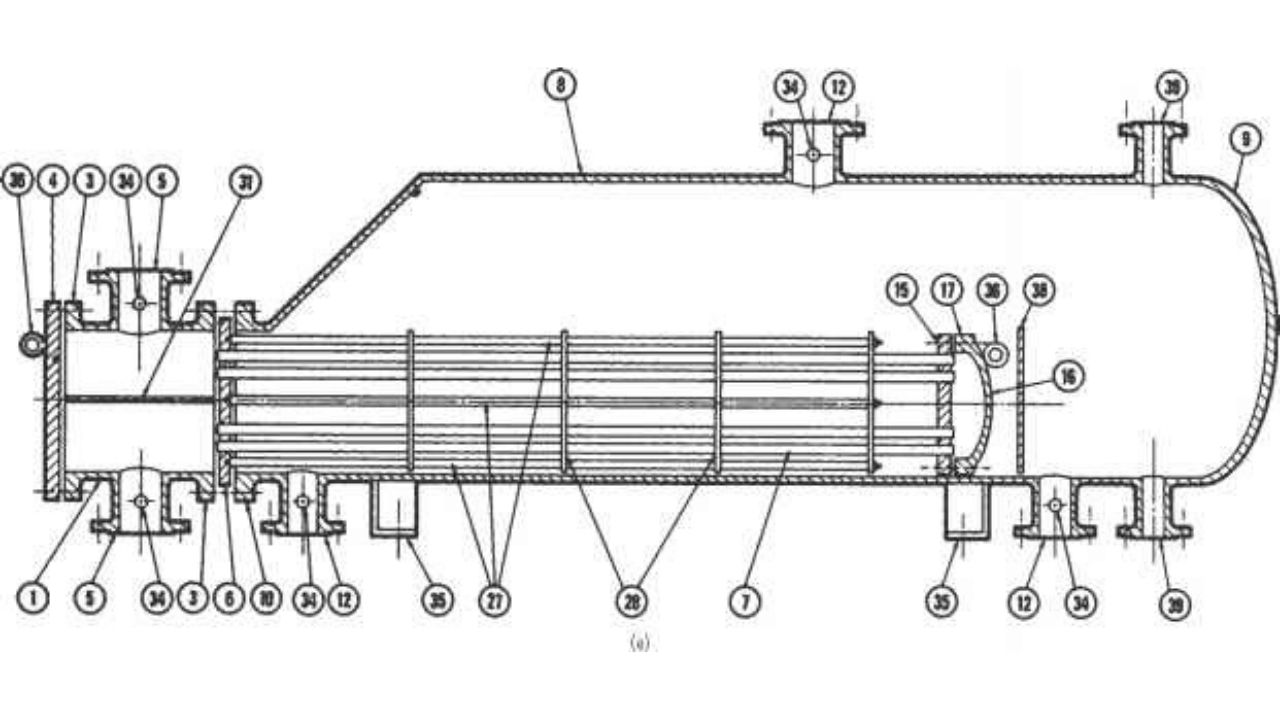

A kettle-type heat exchanger is a type of heat exchanger used primarily for heating a liquid or transitioning it into a vapor phase. It consists of a shell or vessel containing a bundle of tubes. The tubes are typically U-shaped or straight and are immersed in the liquid heated or cooled. Heat transfer occurs between the liquid inside the tubes and the surrounding liquid or vapor.

These exchangers have a similar structure with shell and tube heat exchangers. The main distinction is that the outer shell takes the form of a boiler or boiling pot. The tube bundle is situated within this shell. A kettle reboiler operates by facilitating heat transfer from one fluid to another through a tube bundle.

This type of reboiler keeps the liquid beneath the shell. There, the liquid is in contact with a tube bundle containing the heating medium. The heating medium, which could be steam, passes through the tube bundle and exits as condensate. The liquid from the bottom of the tower to be heated flows from the shell side.

The latent heat of the vaporizing medium (steam) is utilized in vaporizing the liquid on the shell side. K Shell design provides sufficient space to separate the vaporized liquid and vapor. The vaporized liquid flows out from the top of the shell.

Using U-bend tubes allows for free expansion of the tubes and inner separation space is created with a bigger shell diameter. The larger shell diameter also enables internal flow and increases the heat transfer coefficient.

The heating medium on the tube side can vary, such as steam or thermal oil. Load variations are controlled by the flow on the tube side or by adjusting the steam pressure.

A retainer wall or overflow wall can separate the tube bundle from the reboiler section where the remaining liquid is drawn. The tube bundle remains submerged in the liquid. Kettle-type reboilers are reliable and easy to maintain.

While a retainer wall or overflow wall may separate the tube bundle from the reboiler section wher the remaining liquid is absorbed, tube bundle is covered with liquid.

There is a retaining wall or overflow wall. This determines the amount of liquid to be held in the shell to keep the tube bundle submerged in the liquid. The vertical length of the overflow wall is important. For maximum efficiency of an exchanger, the tube bundle should be continuously immersed in the liquid throughout the process.

For more detailed information about kettle-type heat exchanger or to request a quote, you can contact us via the WhatsApp support line, our contact numbers, or by the quote request form available on our website.