Effective exhaust gas waste heat exchangers designed by Erk Proses for industrial plants. Increase energy efficiency by recovering the heat from your systems.

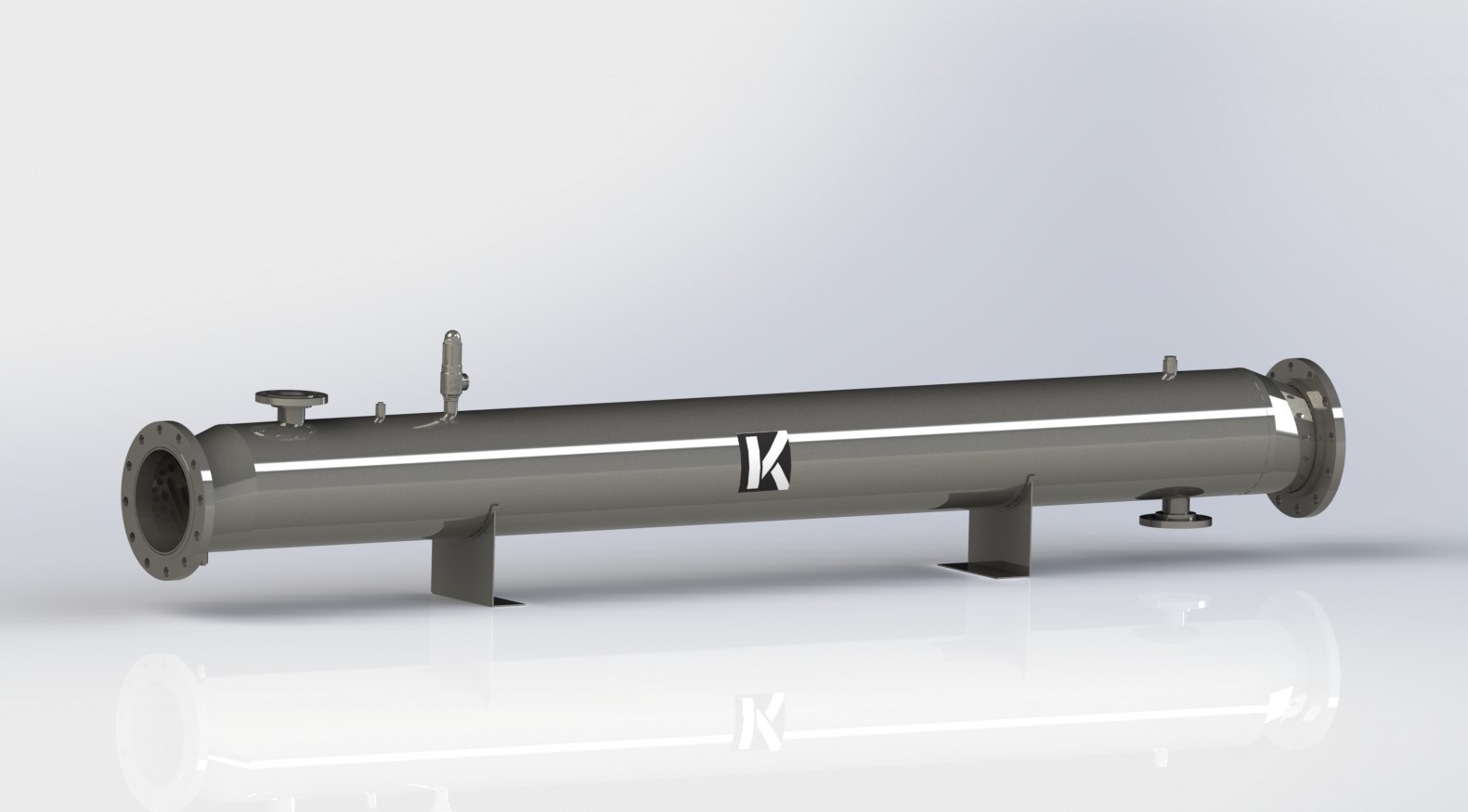

Exhaust gas (waste heat) heat exchanger is a type of heat exchanger used in industrial and automotive applications. Exhaust gas (waste heat) is a byproduct of the combustion process in engines and is in vapor form. The purpose of an exhaust gas (waste heat) exchanger is to transfer the heat from the vaporized exhaust gas to water or another liquid.

Exhaust gas (waste heat) heat exchanger can be utilized to enhance the efficiency and performance of engines. The heat from the exhaust gas can be transferred to water or another liquid and this can ensure cooling of the engine. Additionally, exhaust gas (waste heat) heat exchanger can help reduce the emission of harmful gases into the atmosphere.

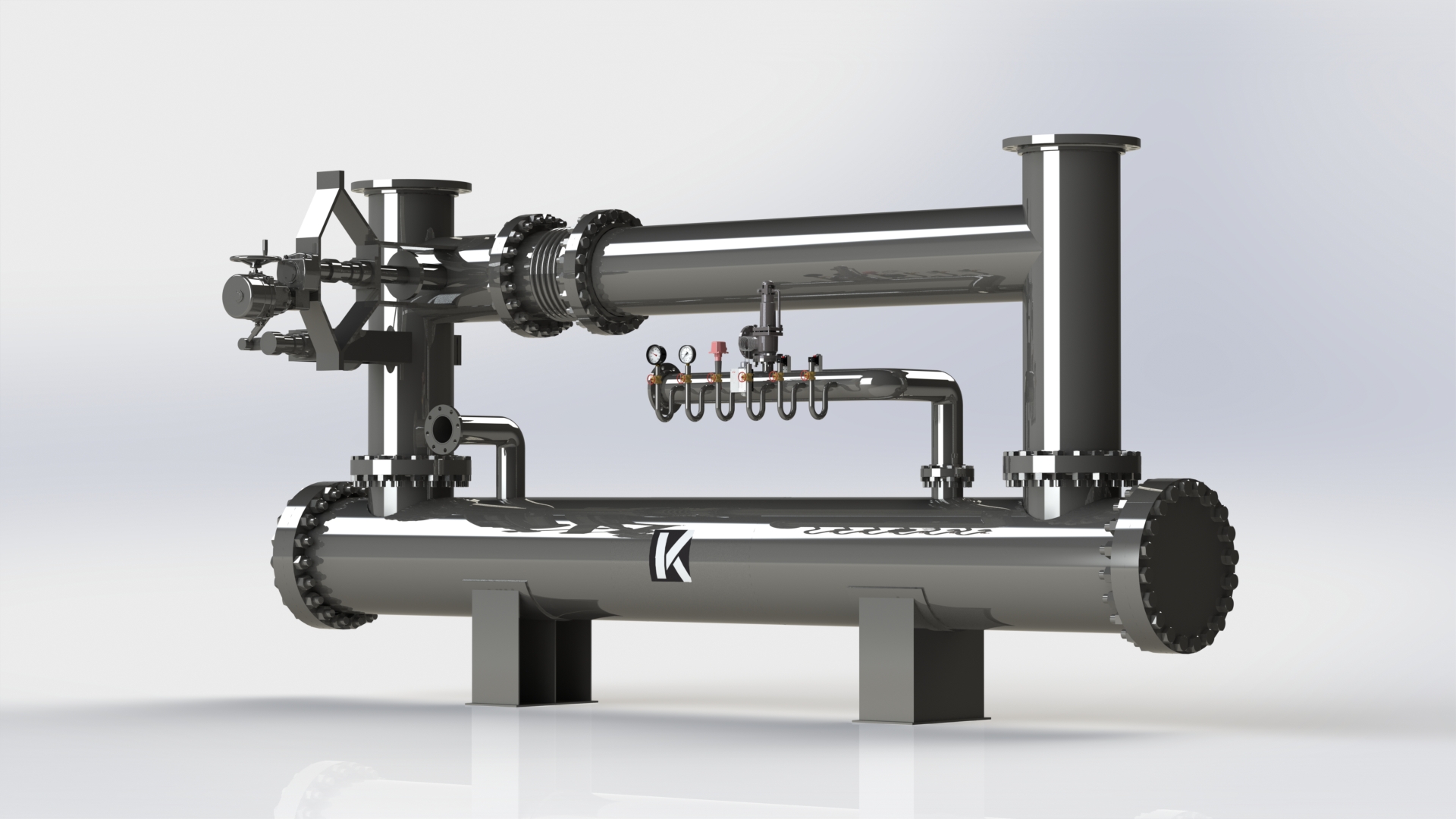

Exhaust gas (waste heat) heat exchanger can be produced in various designs and materials. The materials used can vary depending on the conditions and requirements of the application. Exhaust gas (waste heat) heat exchangers are designed and manufactured based on the suitable materials requested, and these materials such as non-alloy steel and stainless steel can be used according to their thermal and mechanical characteristics in this process. Due to the fact that exhaust gas (waste heat) heat exchangers might not be operational on a 24/7 basis, unlike some other types of exchangers, they should be equipped with a bypass circuit apart from the general structural

requirements. This bypass system is recommended by ERK Proses to be utilized in conjunction with control equipment to manage factors such as temperature and harmful gas content in the exhaust gas.

Safety and control equipment used in exhaust gas (waste heat) exchangers can include:

- Pressure sensors: They control efficiency and safety of the exhaust gas exchanger by measuring

the pressure of exhaust gas.

- Temperature sensors: They control efficiency and safety of the exhaust gas exchanger by

measuring the temperature of exhaust gas.

- Exhaust gas outlet control valves: They are used to control the outlet of exhaust gas.

- Thermostatic controllers: They control efficiency and safety of the exhaust gas exchanger by

measuring the engine’s.

- Pressure limiters: They limit the maximum pressure of exhaust and ensure safety of the exhaust

gas exchanger.

- Thermostatic valves: They are automatically closed if the temperature in the exhaust gas

exchanger exceeds a certain level.

These equipment ensure the efficient and safe operation of exhaust gas (waste heat) heat exchangers and enhance safety in case of any malfunction of or damage to the exchanger.

ERK Proses, with its expert technical team, provides services to its valued customers in the thermal and mechanical calculations, design, and production of these exchangers. For more detailed information about exhaust gas (waste heat) heat exchanger or to request a quote, you can contact us via the WhatsApp support line, our contact numbers, or by the quote request form available on our website.