Effective biogas heat exchangers designed by Erk Proses for industrial plants. Optimize the performance of your biogas systems with their high efficiency and durable structures.

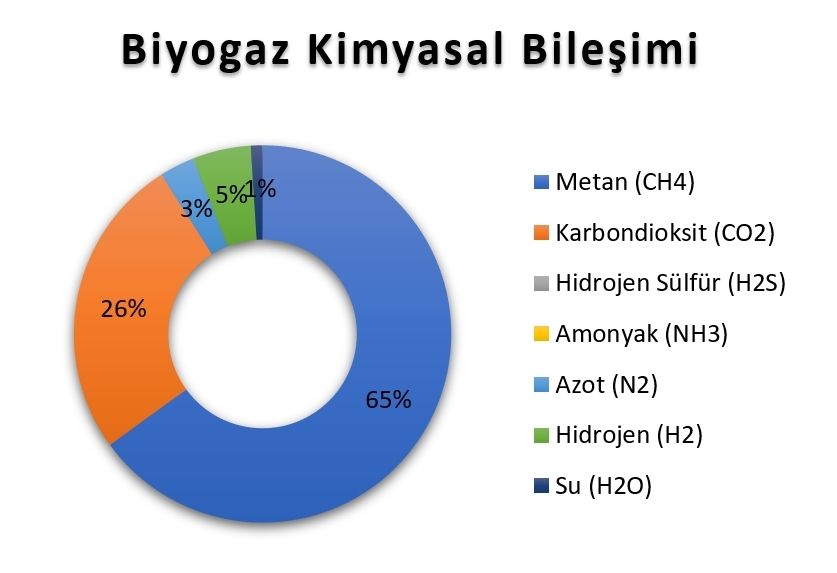

Biogas is a gas formed by degradation of organic substances by bacteria under anaerobic (oxygen- free) conditions. Biogas consists of components such as methane (CH4) and carbon dioxide (CO2), and it is typically produced in places where waste is generated, on farms, or in biogas plants. Biogas offers numerous benefits such as energy production, waste management, and reduction of air pollution and it can be used as an environmentally friendly alternative energy source.

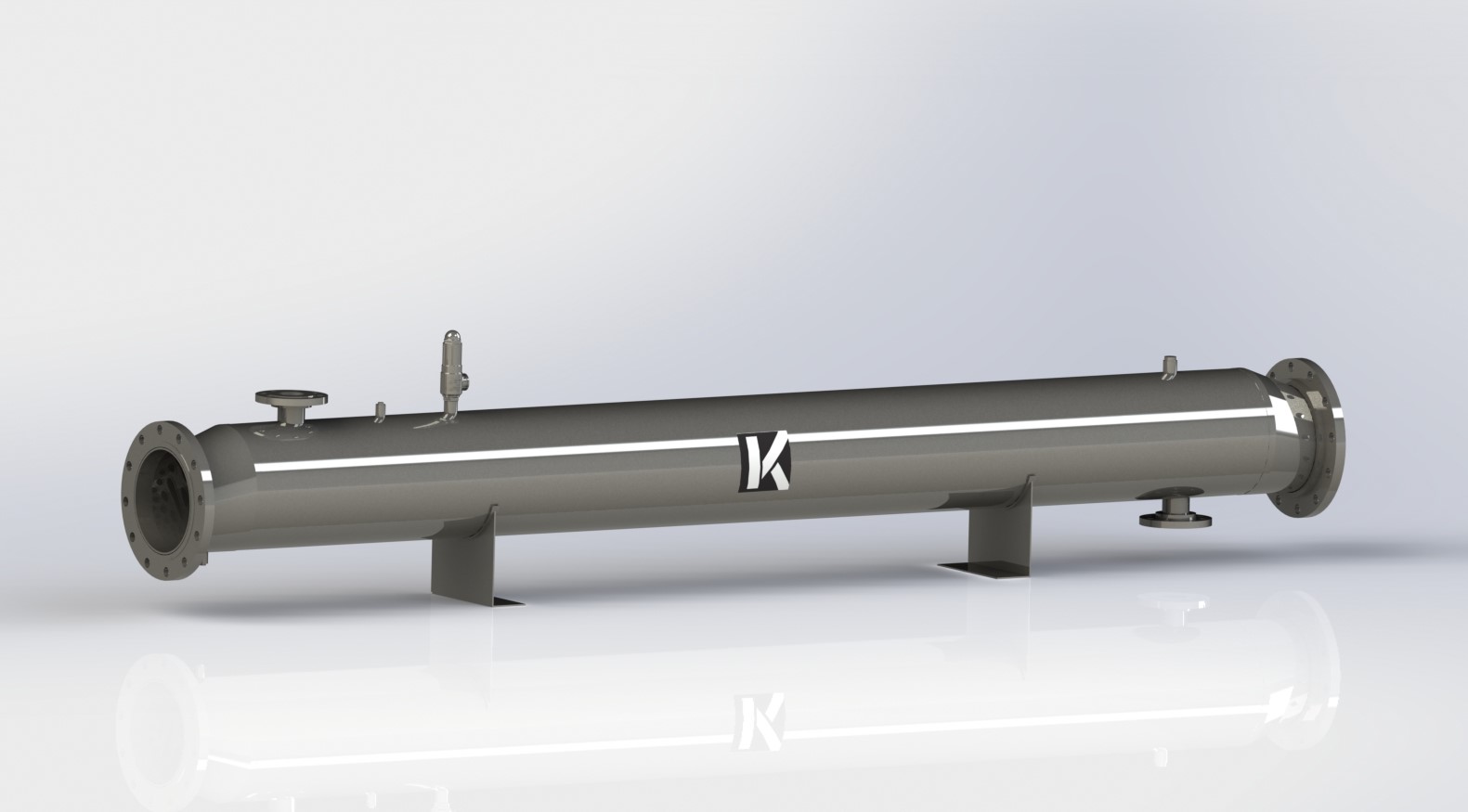

In a biogas plant, exchanger is used to carry out various processes during the biogas production process, aiming to optimize the quality and efficiency of biogas. Biogas exchangers are used to fulfill functions such as cooling the biogas and condensing the water vapor in its content. These exchangers are essential to optimize the operation and efficiency of the biogas plant, ensuring its safe and efficient operation.

A biogas cooling exchanger is a device used to reduce or control the temperature of the hot biogas generated in the biogas production process. Quality and efficiency of biogas can be increased through this exchanger and the plant’s overall efficiency can be ensured. Biogas dehumidifying exchangers are equipment used to dry or reduce the moisture level of the humid biogas generated during the biogas production process. With the help of this exchanger, quality and efficiency of biogas can be improved and the plant can be operated efficiently.

As an option, in the biogas production process, exchangers can be used for energy recovery purposes. Additionally, pre-heating of dehumidified biogas or biogas with the humidity reduced before combustion can lead to more effective combustion. ERK Proses, with its expert team, is ready to provide you with all types of exchangers in this direction according to your requirements.

The materials used in manufacturing of biogas exchangers can vary based on the chemical characteristics of the gases available in the biogas and the operating conditions of the plant. Use of these materials ensures efficient and safe operation of biogas exchangers and contributes to the long-term operation of the plant. Generally, materials such as nickel alloys and corrosion-resistant materials as being stainless steel derivatives are used in manufacturing of biogas exchangers. Stainless steel is used to prevent the presence of chemical substances in biogas that could cause corrosion or structural degradation.

For more detailed information about biogas heat exchangers or to request a quote, you can contact us via the WhatsApp support line, our contact numbers, or by the quote request form available on our website.