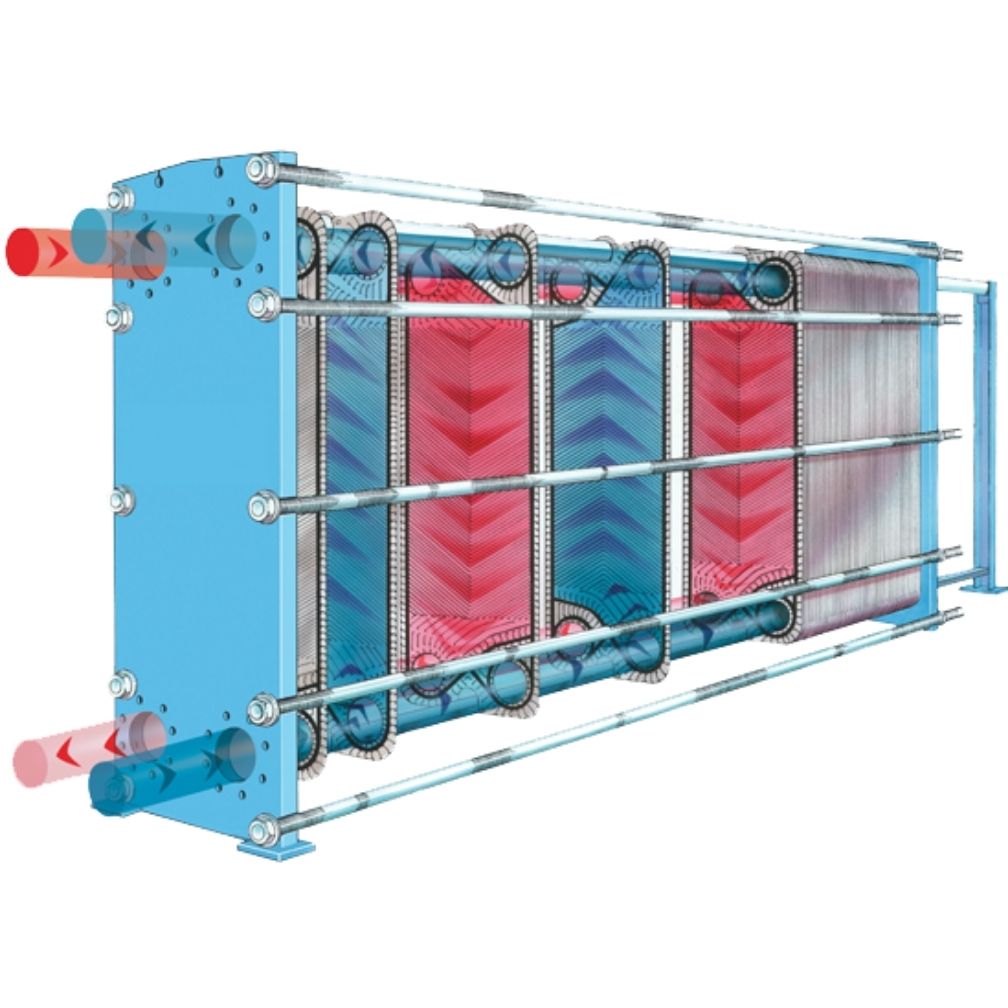

Plate heat exchangers are equipment that provide heat transfer between fluids with two different temperatures.

Plate heat exchangers are equipment that provide heat transfer between fluids with two different temperatures. Between the heat transfer plates placed between two bodies, one fixed and the other movable, the fluids move in the opposite direction and leave the heat exchanger by performing heat transfer without mixing with each other. Cold fluid is on one side of the plate and hot fluid is on the other. Thanks to the gaskets located between the plates, the fluids do not mix with each other and sealing is ensured in the volume created between the plates.

Plate heat exchangers consist of following equipment.

• Fixed and movable body,

• Heat transfer plates,

• Sealing gaskets,

• Upper and lower carrier and centering rods,

• Studs and other fastening equipment,

• Input - output port or connections,

• Rear support profile,

• Body fixing feet.

These types of heat exchangers are suitable for useing in many types of applications and industries. By removing the stud connections forming the heat exchanger, the heat exchanger can be easily disassembled and maintained. In addition, the desired level of capacity can be increased by increasing the number of plates afterwards. Thanks to the high turbulent flow between the prominent formed plates in the plate heat exchanger, the pollution is kept at a minimum level and thus they do not require frequent maintenance.

The generally used materials of the main components that make up the plate-seal heat exchanger for different fluid, temperature and process compatibility are as follows.

Body Materials

*Carbon Steel

*Stainless Steel

*Stainless Coating Plate

Materials

*AISI304, AISI316L Stainless Steel

*Titanium

*Hastelloy Alloys Gasket Materials

*NBR, HNBR

*EPDM, EPDM-HT

*FKMA, FKMG

ERK with its expert staff, in accordance with its permanent mission, undertakes to offer the most accurate product or service selection by considering the customer benefit as an ethical criterion in every customer request and to produce or serve in line with the most up-to-date standards and technologies.