Economizers and recuperators are products used to recover energy from the waste heat discharged from the chimney and to meet the need for hot water or hot air in accordance with the operating needs.

Economisers are products that provide energy recovery from the waste heat discharged from the chimney in steam, hot oil, hot water, boilers and cogeneration systems and are used for heating boiler feed water in accordance with the operational needs, in-house hot water needs, as a heat source for a different device and for similar purposes.

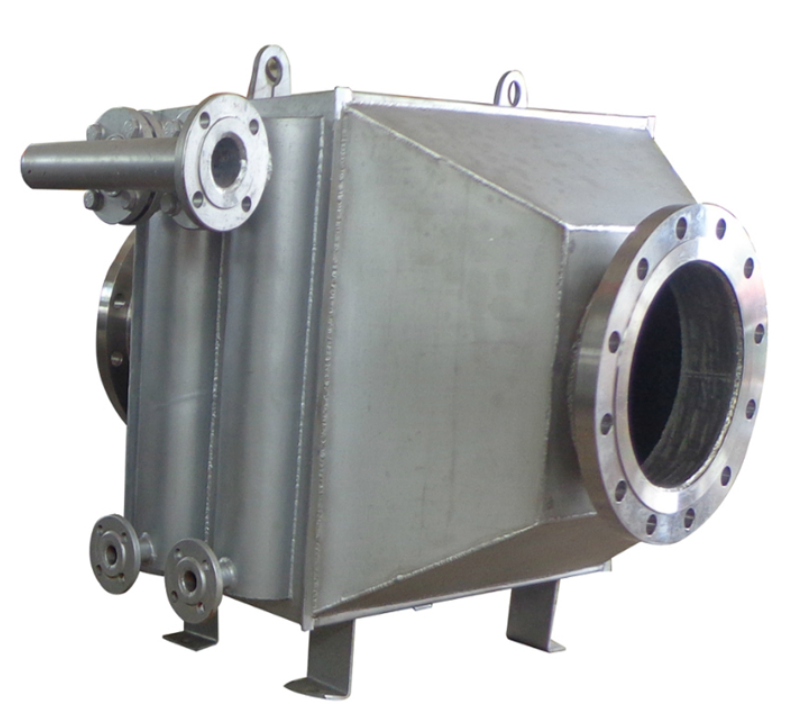

Recuperators, on the other hand, are products used for burner air preheating, process hot air needs, drying and similar purposes needed in the business by making use of the waste heat discharged from the chimney.

- Power Plants,

- Hydrocarbon processing plants,

- Iron - Steel and metal production facilities,

- Chemical substance manufacturing facilities,

- Food processing facilities,

- Paper production facilities,

- It is used as efficiency increasing equipment in HVAC and many other industrial or comfort applications.

Fuel type and stack gas temperature are very important in the design of related products. They can be manufactured in two different types as condensing and non- condensing. In case of non-condensing design in natural gas fueled systems, the stack gas can be reduced to an outlet temperature of 110 ̊C while stack gas outlet temperature can be designed up to 50 ̊C in condensing types. In solid-liquid fuel systems (fuel-oil, coal, diesel etc.), the stack gas outlet temperature of 130-180 ̊C in non-condensing designs varies according to the fuel type, while designs can be made at a stack gas outlet temperature of up to 50- 55 ̊C in condensing types.

ERK offers related products with proven designs, taking into account all impermeability and condensation criteria, according to customer process data. Product thermal and mechanical calculations are made in accordance with the TEMA standard and the 2014/68/EU PED pressure vessels directive. Economisers and recuperators are made of carbon steel and stainless steel, taking into account the fluid data.

ERK with its expert staff, in accordance with its permanent mission, undertakes to offer the most accurate product or service selection by considering the customer benefit as an ethical criterion in every customer request and to produce or serve in line with the most up-to-date standards and technologies.