What is Heat Exchanger? What are the Types and Application Areas?

2024-03-01 02:36:56

Heat exchangers are products used to realize heat transfer between fluids that allow heat to be transferred from one medium to another.

Heat exchangers are products that enable the transfer of heat from one medium to another and are generally used to transfer heat between fluids in the liquid and gas phase. This thermal equipment is a critical component that is frequently used in industry and increases the efficiency of processes. Heat exchangers enable heat transfer with different operating principles depending on the areas of use in various types.

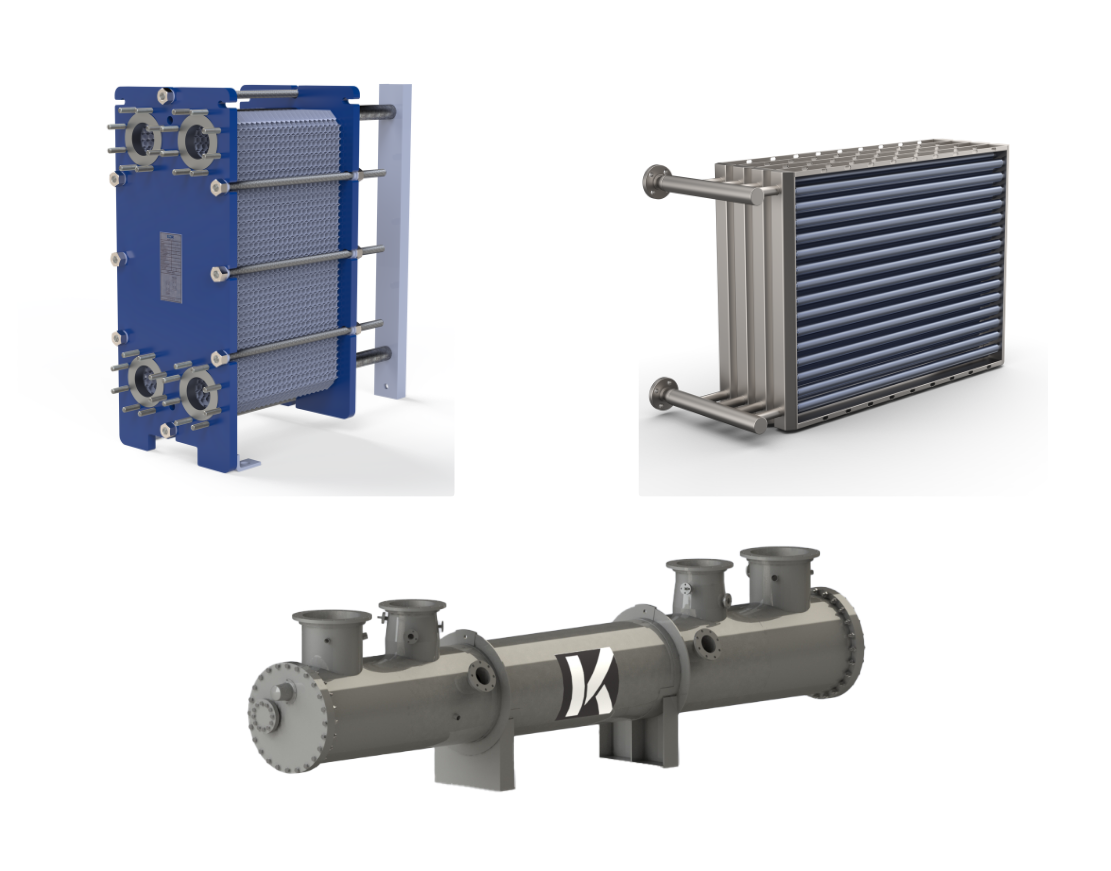

Heat Exchanger Types

Heat exchanger types can be grouped under 3 main headings according to their geometric structures. These are tubular heat exchangers, plate heat exchangers and finned heat exchangers respectively. There are also sub-product groups under each product group. Let us briefly examine below what the relevant heat exchanger types are under general headings and which products are included in the sub-product groups.

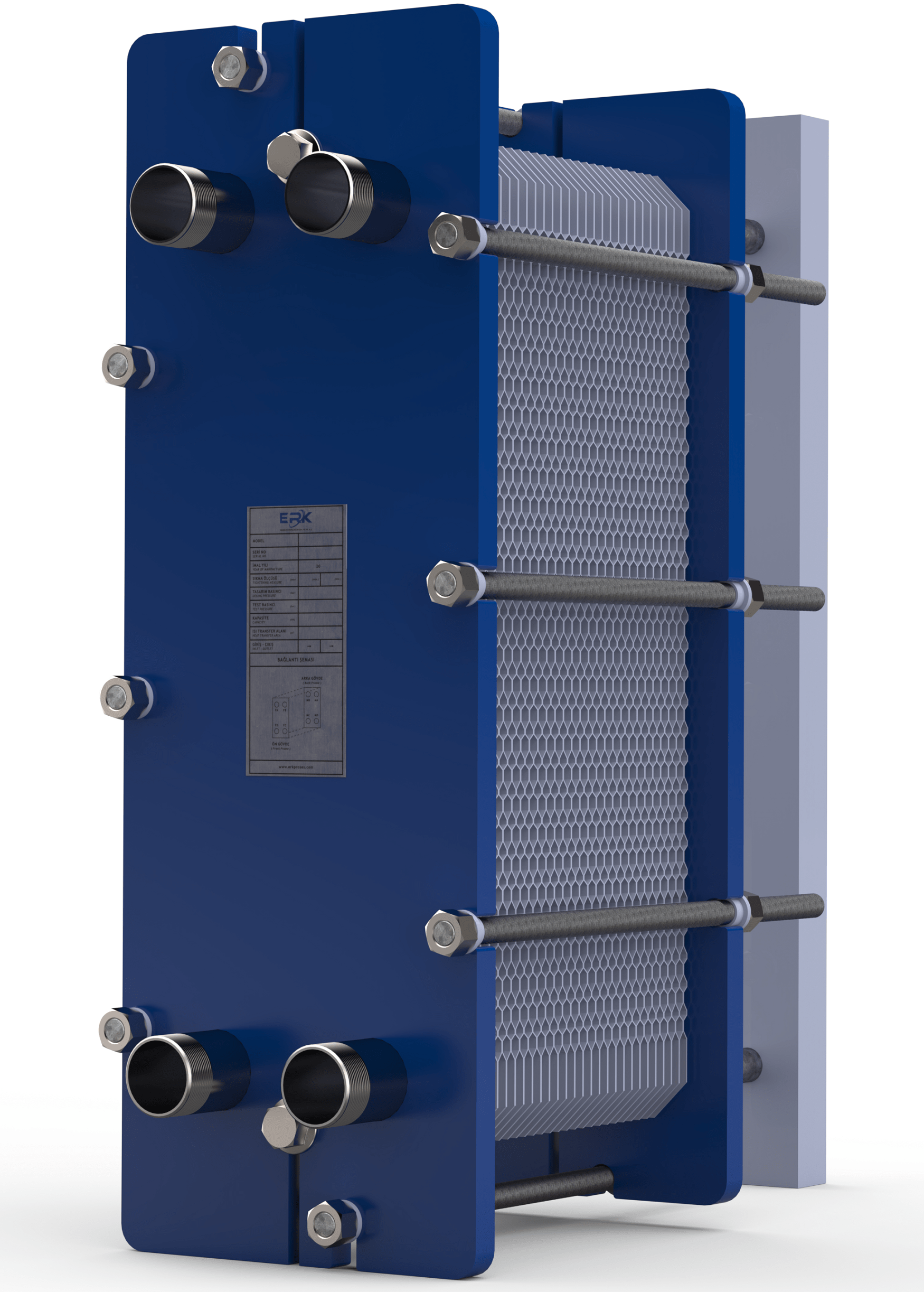

1.) Plate Heat Exchangers: Plate heat exchangers consist of thin metal plates and the flow of liquids or gases is provided between these plates. Plate heat exchangers stand out with their high heat transfer coefficient and compact design. This type of heat exchangers are widely used in the transfer of hot water, cold water, steam and other fluids. Sub-product groups are divided into gasketed plate heat exchangers, spiral plate heat exchangers, brazed heat exchangers and lamellar heat exchangers.

2.) Tube Heat Exchangers: Tubular heat exchangers consist of a bundle of tubes through which a fluid flows and a shell with another fluid outside. These exchangers are effective in transferring large fluid volumes and are generally preferred in industrial heat transfer applications. Sub-product groups are divided into body tube heat exchangers, double tube heat exchangers and spiral tube heat exchangers. Within each sub-product group, product groups can be examined under different headings in accordance with their structure and function.

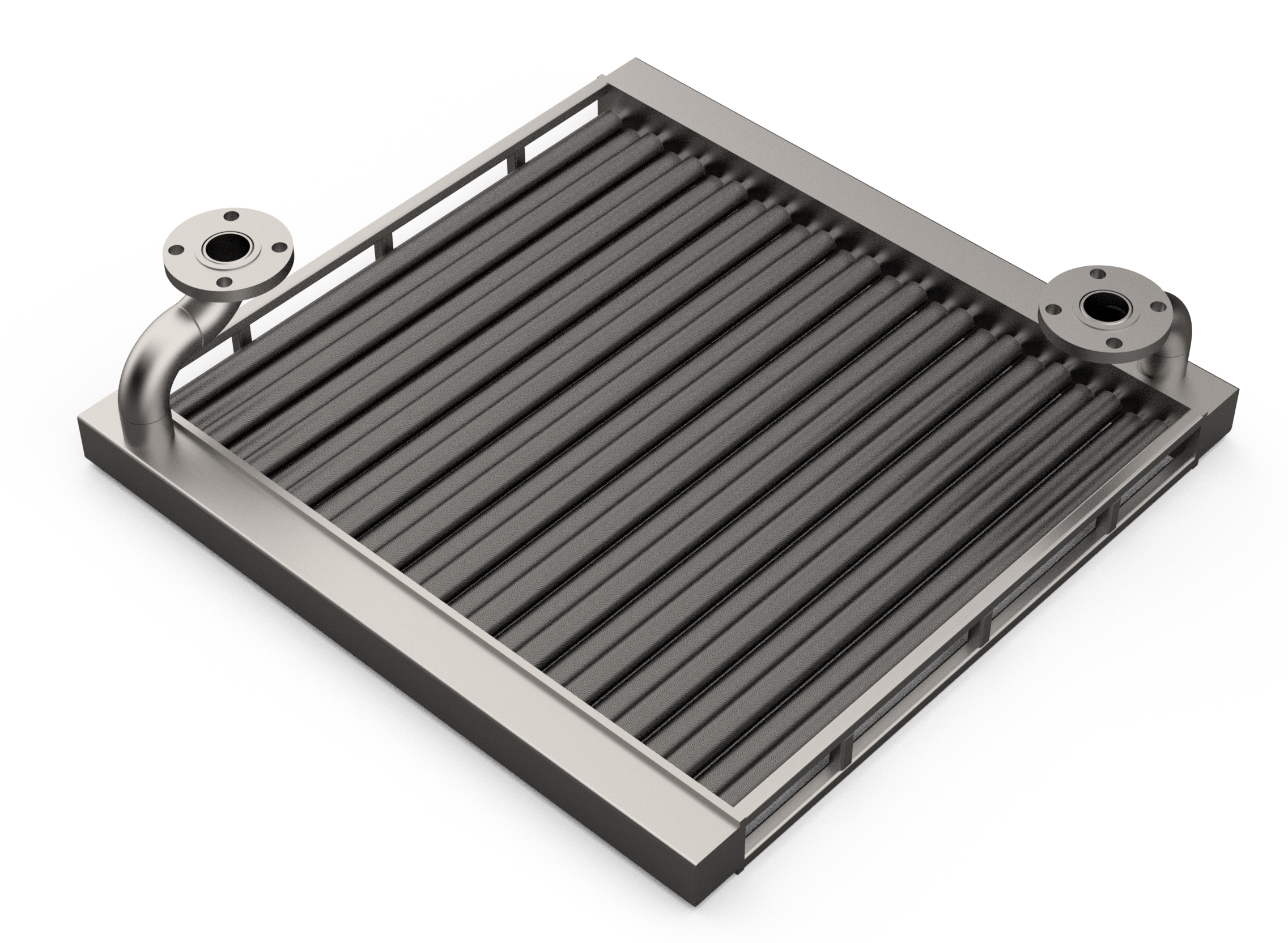

3.) Extended Surface Heat Exchangers: Extended surface heat exchangers are devices with fins or attachments on the primary heat transfer surface (tubular or plate) to increase the heat transfer area. Since the heat transfer coefficient on the gas side is known to be much lower than on the liquid side, finned heat transfer surfaces are used on the gas side to increase the efficiency of heat exchangers when the heat transfer coefficient on one or both sides is low and a compact heat exchanger is needed. Sub-product groups are divided into finned plate heat exchangers and finned tube heat exchangers.

Usage Areas of Heat Exchangers

Heat exchangers are widely used in many industrial processes. These include petrochemical, food and beverage industry, power generation, HVAC systems, chemical processes and marine. Heat exchangers are used in these sectors for a variety of purposes such as heating, cooling, condensing, evaporation and heat recovery.

Working Principle

Heat exchangers basically realize heat transfer using the temperature difference between two fluids. These fluids usually flow parallel or counter-current to each other. Heat transfer takes place through the surfaces where the fluids come into contact and is directly proportional to the temperature gradient.

Materials and Standards

The materials used in heat exchanger manufacturing vary depending on application requirements and operating conditions. Materials such as stainless steel, carbon steel, copper and aluminum are frequently preferred. Heat exchanger designs are developed in accordance with international standards such as ASME, TEMA, API and these standards are taken into consideration during the manufacturing process.

Software and Design

Software programs used in heat exchanger design allow engineers to create efficient designs and predict performance. With these software tools, optimized heat exchanger designs are provided by taking into account factors such as fluid dynamics, heat transfer and material selection.

ERK Proses provides you, our valued customers, with long-lasting product usage, quality and safe product supply by providing heat exchanger selection according to your demand and needs. In addition to on-site or online exploration services, we are always with our valued customers with our expert staff in turnkey project services, service and maintenance services, design and manufacturing as ERK Proses.