What are The Milk and Pasteurization Heat Exchangers?

2024-03-06 02:37:07

Milk and pasteurization heat exchangers play a crucial role in processing milk safely and delivering it to consumers.

Milk and pasteurization heat exchangers play a crucial role in processing milk safely and delivering it to consumers. In this article, we will provide you with general information by first explaining the basic concepts of these exchangers, which are used for heating or cooling processes of milk and related products.

Milk and Pasteurization Heat Exchangers: Basic Information

Milk, the first source of nutrition for mammal offspring, provides high nutritional value for energy and growth. It also contains antibodies that protect young mammals from infections.

Due to the presence of numerous microorganisms naturally, milk requires hygienic processing. Pasteurization, an essential process for eliminating harmful bacteria and microorganisms from milk, involves milk and pasteurization heat exchangers.

The term "pasteurization" was coined by Louis Pasteur, who conducted fundamental studies on the lethal effects of heat on microorganisms and the use of heat as a protective technique in the mid-19th century. Pasteurization of milk can be defined as any heat treatment that definitively destroys microorganisms without significantly affecting the physical and chemical properties of milk.

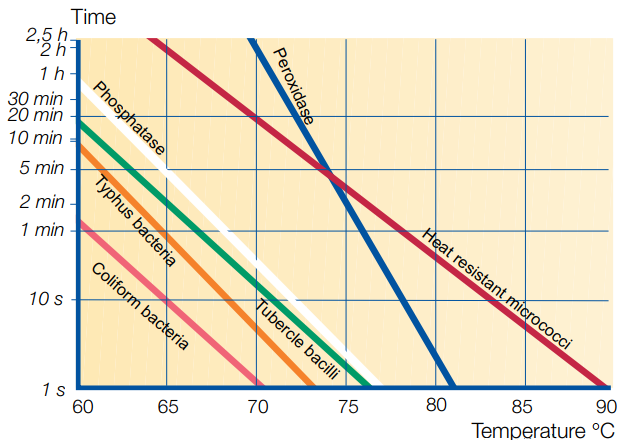

The most resistant organism found in milk is tuberculosis bacillus (T.B.), believed to be killed by heating milk to 63°C for 10 minutes or 30 minutes at 63°C for complete safety. Therefore, any heat treatment that destroys T.B. is reliable for eliminating all other pathogens in milk. In addition to pathogenic microorganisms, milk contains various substances and microorganisms that can affect the taste and shelf life of various dairy products. Thus, the secondary purpose of heat treatment is to destroy as many of these organisms and enzymatic systems as possible. This requires a more intensive heat treatment than necessary to kill pathogens.

The need for the secondary purpose of heat treatment over time has arisen with the extended time between deliveries. Despite modern cooling techniques, it has been understood that microorganisms have more time to multiply and develop enzymatic systems. Additionally, to overcome problems such as the degradation of milk components and pH drop, the heating and cooling processes must be applied as quickly as possible after reaching the milk processing center.

The combination of temperature and holding time is crucial since it determines the intensity of heat treatment. Intensive heat treatment of milk is microbiologically desirable, but it poses a risk of negative effects on the appearance, taste, and nutritional value of milk. Proteins in milk denature at high temperatures, significantly affecting the cheese-making properties of milk. Therefore, the selection of time/temperature combinations is an optimization issue that considers both microbiological effects and quality factors.

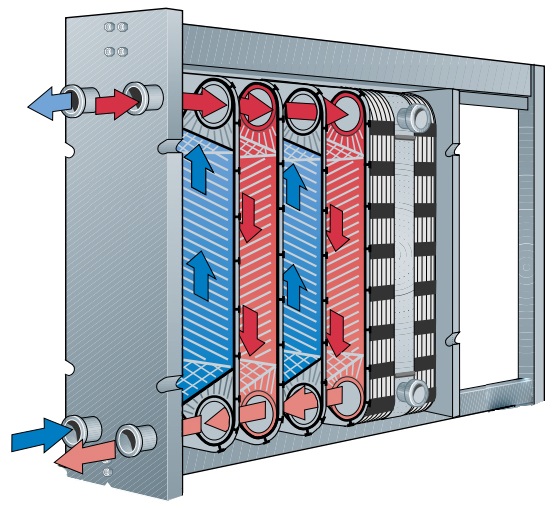

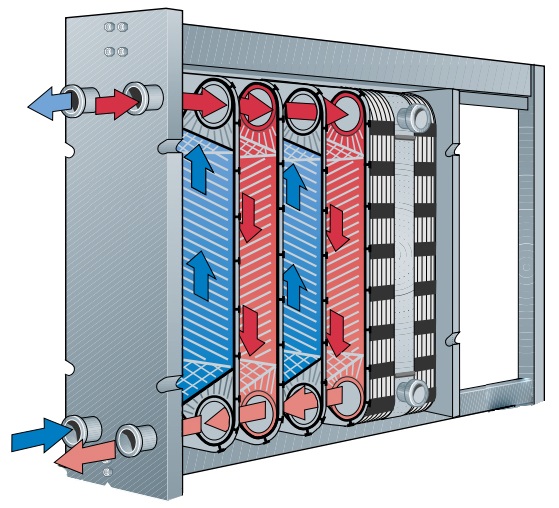

The pasteurization process aims to kill microorganisms by heating or cooling milk at a specific temperature for a certain duration. Pasteurization exchangers are systems consisting of plates that rapidly heat or cool milk. There are various pasteurization methods and cycles used for different applications such as the production of specific products for commercial purposes. These methods include, but are not limited to, thermization, LTLT (low temperature, long time) milk pasteurization, HTST (high temperature, short time) milk pasteurization, HTST cream pasteurization, ultra-pasteurization, and UHT (ultra-high temperature) processes. In addition to these processes, various operations such as preheating, heating, cooling, regenerative heating, and cooling are present in the milk processing industry.

In many cases, a product needs to be heated for a specific process and then cooled afterward. Cooled milk is heated to the pasteurization temperature, which ranges from 4°C to 72°C. It is held at this temperature for 15 seconds and then cooled back to 4°C. The heat of pasteurized milk is utilized to warm cold milk. Incoming cold milk is simultaneously preheated by the previously cooled outgoing hot milk. This allows for energy savings in both the heating and cooling processes. The operation takes place in a heat exchanger. Approximately 94-95% of the heat content of pasteurized milk can be recycled.

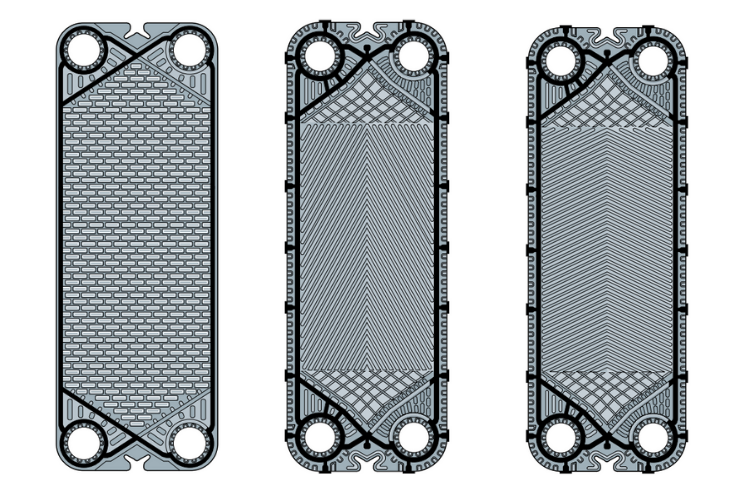

ERK Proses milk and pasteurization heat exchangers have a structure consisting of specially designed plates. These plates ensure the rapid and homogeneous processing of milk by providing an equal distribution of the milk's surface area with a high heat transfer coefficient. Additionally, they are made of materials that are easily cleanable and maintainable to meet hygiene standards.

The plumbing connections of ERK Proses hygienic plate heat exchangers come in threaded or clamp types. The body and main supporting frame structure are made of AISI 316 quality stainless steel, and all contact points with the fluid and heat transfer surface areas are also made of AISI 316 quality stainless steel.

Surface contamination in milk and pasteurization exchangers can occur depending on the process. Due to denaturation, some proteins in milk adhere to the plate surface when milk is heated to temperatures of 90˚C and above. In such cases, CIP (Clean in Place) processes must be planned correctly for automatic cleaning of the plates. Otherwise, microorganisms adhering to the surface can negatively impact heat transfer, reducing exchanger performance, affecting both fluid contamination and the inability to maintain the process at the correct thermal values.

ERK Proses Guarantee in Milk and Pasteurization Heat Exchangers

ERK Proses is a reliable brand specializing in the design of milk and pasteurization heat exchangers. Each product is manufactured in compliance with quality and safety standards. To ensure maximum efficiency and reliability in milk processing processes and for all your requests related to milk exchangers, ERK Proses is always there for you.