Pressure Vessels: Types, Applications and Design Standards

2024-03-09 02:37:14

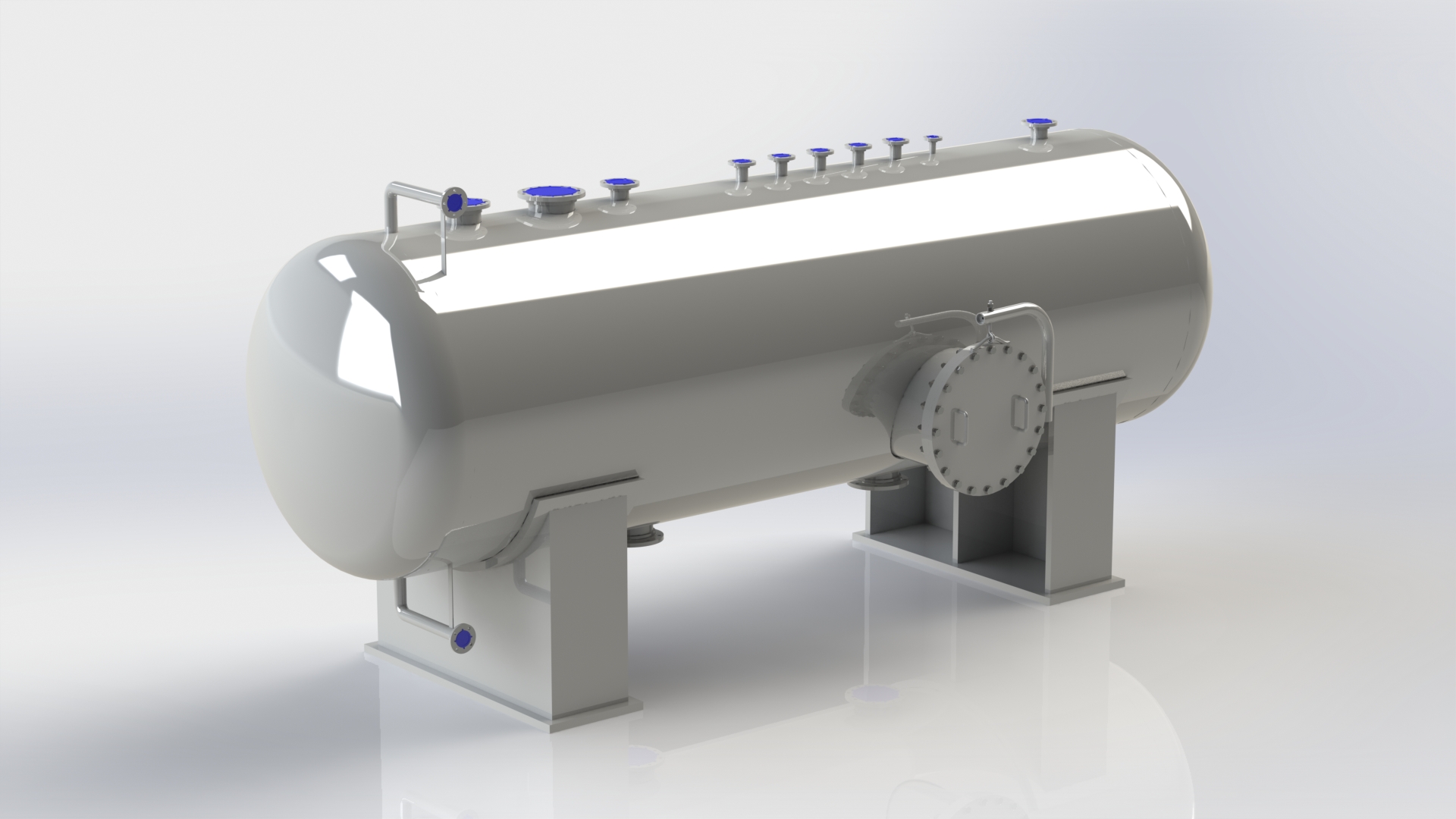

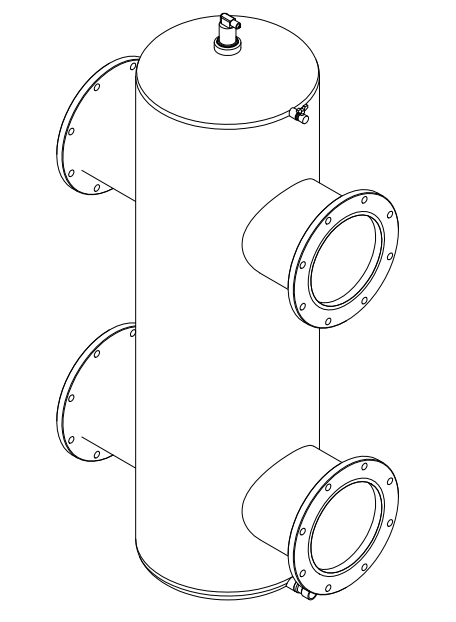

Pressure vessels are closed-volume systems where gases or liquids are subjected to a specific pressure.

Pressure vessels are closed-volume systems where gases or liquids are subjected to a specific pressure. These vessels are widely used in various industries such as industrial, energy, chemical, HVAC, etc., tailored to meet specific needs.

These vessels can be customized according to special industrial requirements and typically need to possess high strength, leak-tightness, and durability characteristics. In addition to industrial applications, research and development activities play a role in the continuous improvement and diversification of pressure vessels, incorporating new materials and design technologies. This allows for the ongoing enhancement and diversification of pressure vessels. Pressure vessels used in our buildings are generally found in various applications such as water systems and heating, ventilation, and air conditioning (HVAC) systems.

Pressure vessels can be manufactured in different material types based on the fluids used in the process and mechanical design data. Commonly, pressure vessels are produced in a variety of materials such as carbon steel, stainless steel, aluminum alloys, fiberglass, or composites. Carbon steel is preferred in general industrial applications due to its durability and economic feasibility, while stainless steel is favored in industries such as chemistry for its corrosion resistance against fluids with high corrosive effects.

The sectors where pressure vessels are used are discussed under the following headings:

a.) Petroleum and Gas Industry

Pressure vessels are widely used in facilities such as petroleum refineries, LNG & LPG processing, and storage plants. Storage tanks, gas cylinders, and pressure reactors are common pressure vessels used in these industries.

b.) Chemical Industry

Pressure vessels are used in chemical manufacturing plants as well as laboratories and research centers studying chemical derivatives. Chemical reactors, pressure tanks, boilers, and tubes are examples of pressure equipment used in chemical processes.

c.) Energy Production Plants

Pressure vessels play a significant role in energy production facilities such as power plants, thermal energy plants, and nuclear power plants. They are commonly used in steam boilers, turbines, and pressure cylinders, contributing to energy conversion and transmission.

d.) Food and Beverage Industry

Pressure vessels are utilized in food processing and beverage production facilities, including fermentation tanks, pasteurization equipment, carbonation systems, and other areas.

e.) Automotive Industry

Pressure vessels are employed in automotive production facilities for applications such as compressed air systems, paint spraying equipment, and hydraulic systems.

f.) Medical, Health, and Pharmaceutical Industry

In pharmaceutical manufacturing facilities, pressure vessels like sterilization equipment, fermentation tanks, and pressure reactors are used. Pressure vessels are also employed in hospitals and laboratories for storing medical gases or in cooling and heating processes.

g.) Maritime

Pressure vessels are used on ships for fuel storage and balancing systems.

h.) HVAC Systems

Pressure vessels are commonly used in buildings and hotels for water storage, booster systems, expansion tanks, air separators, sediment traps, and gas storage systems.

Some fundamental design standards are discussed as follows:

a.) ASME (American Society of Mechanical Engineers): Establishes international design standards for pressure vessels.

b.) PED (Pressure Equipment Directive): Specifies requirements for the design and manufacture of pressure equipment in the European Union.

c.) API (American Petroleum Institute): Sets standards for pressure vessels used in the petroleum and gas industry.

As ERK Process, we operate in this sector with our expert design and manufacturing team specializing in pressure vessels. We provide quality products and services to our valued customers through the production of pressure vessels and various equipment.

Our company utilizes up-to-date design software that adheres to current standards, ensuring that we offer you a high-performance, quality, and safe product. Through rigorous controls and inspections during the manufacturing process, we deliver long-lasting products that meet standards.

If you have inquiries or requests for information regarding pressure vessels, we encourage you to contact us. Our team of expert engineers is ready to provide you with product proposals tailored to your needs as quickly as possible, offering the most suitable solutions to our valued customers.