Timing and Importance of Maintenance:

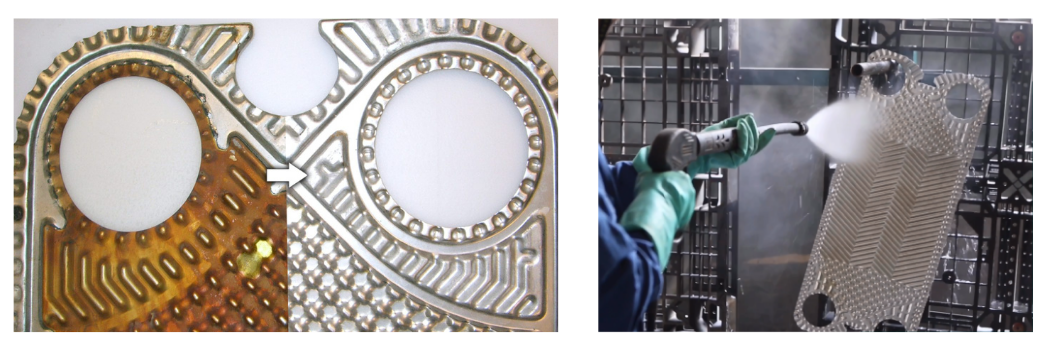

Regular maintenance of plate heat exchangers is the key to long-lasting and reliable performance. It's generally recommended to perform maintenance once a year, but it can be more frequent depending on operating conditions.

ERK Proses can plan your maintenance processes along with your exchanger purchases. Since maintenance planning directly affects the lifespan of products and the efficiency of the exchanger, it is crucial not to delay product service-maintenance processes.

Tips to Extend the Life of Plate Heat Exchangers:

Regular Maintenance: Regular maintenance at specified intervals extends the life of the exchanger and prevents sudden breakdowns. ERK Proses engineers provide free on-site service and maintenance support for your needs. After determining periodic processes, an agreement can be reached to provide on-site service, offering instant solutions to your needs.

Use of Quality Parts: The quality of spare parts used during maintenance affects the durability and performance of the exchanger. ERK Proses supplies quality and reliable plates, gaskets, and spare parts for both its own brand and all known brands and models in the market.

Professional Support: Working with a technical team of experts for maintenance processes ensures your exchanger stays in top condition. ERK Proses provides endless confidence to its valued customers with its team of expert engineers and service staff.