Steps for Heat Exchanger Maintenance

a.) Visual Inspection: Conducting a visual inspection of the external surface and connection points of the heat exchanger is important for identifying issues early. Signs of rust, corrosion, or leaks should be observed.

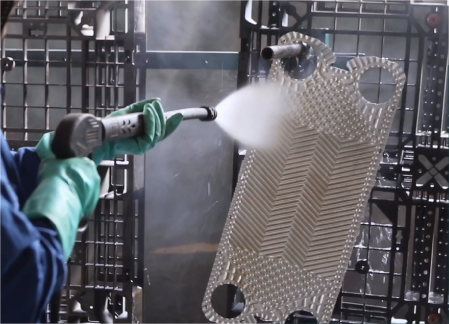

b.) Cleaning: Regular cleaning of the internal and external surfaces of the heat exchanger prevents scaling, sediment, or dirt accumulation. Effective cleaning should be done using chemical cleaning agents or special pressure equipment.

c.) Inspection: Beyond visual inspection, inspections such as checking for thinning or perforation of heat exchanger plates, ultrasonic testing of tube wall thickness in shell and tube heat exchangers, and similar checks for leaks should be performed during maintenance.

d.) Repairs and Replacements if Necessary: Any damage detected during maintenance should be immediately repaired or parts should be replaced. Addressing any issues that affect the performance of the heat exchanger is crucial.

e.) Pressure Testing: After maintenance work is completed, if possible, the heat exchanger should be subjected to a pressure test before being put back into operation. If no issues are observed after the pressure test, the heat exchanger is connected to the system and brought online.