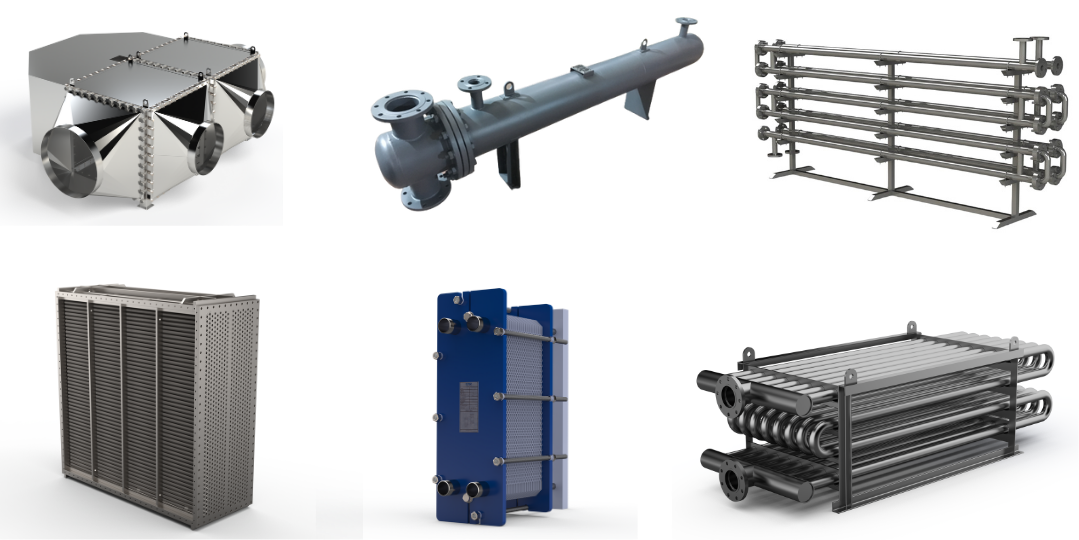

Heat exchangers used in industrial processes are critical for heat transfer. However, selecting the right type of heat exchanger is key to achieving effective performance. Here is a detailed examination of the factors to consider when selecting a heat exchanger type:

1.) Selection Based on Application Type:

Which fluids will be involved in the heat transfer?

What are the factors such as varying temperatures, pressures, and flow rates?

Understanding the specifics of your industrial process is a fundamental step in determining the correct type of heat exchanger.

2.) Material Selection:

Heat exchangers are typically made from various materials such as stainless steel, carbon steel, and copper alloys.

The chemical composition and temperature-pressure conditions of the working environment determine the appropriate material selection.

3.) Heat Exchanger Efficiency:

Factors such as heat transfer coefficient, pressure drop, fluid losses, and stability affect the efficiency of the heat exchanger.

Higher efficiency reduces energy and operating costs while enhancing performance.

4.) Ease of Installation and Maintenance:

Easy installation and maintenance of heat exchangers are crucial for operational continuity.

Modular designs, quick setup, and low maintenance requirements reduce operating costs.

5.) Size and Capacity:

Choosing a heat exchanger of the appropriate size and capacity to meet process requirements is important.

Correct sizing increases efficiency while optimizing energy and material use.

6.) Compliance and Standards:

Ensuring the heat exchanger complies with industry standards and regulatory requirements is important for safety and legal compliance.

Attention to quality certifications and certifications ensures long-term compliance.

7.) Cost-Effectiveness Analysis:

Heat exchanger selection includes not only initial costs but also operating costs over its lifetime.

An effective cost selection should consider factors such as energy consumption, maintenance costs, and efficiency over its lifetime.

Selecting the right type of heat exchanger directly impacts the efficiency, safety, and sustainability of industrial processes. By considering the factors above, you can choose the heat exchanger type that best meets the needs of your business and ensure the use of reliable products for the long term. Please feel free to contact us if you have any additional questions or require detailed information. Our professional team will be pleased to assist you.