What are The Advantages of Using Brazed Heat Exchanger?

2024-03-13 02:37:21

Brazed heat exchangers are essential industrial devices that facilitate heat transfer from one liquid fluid to another or from a liquid to a different gas fluid.

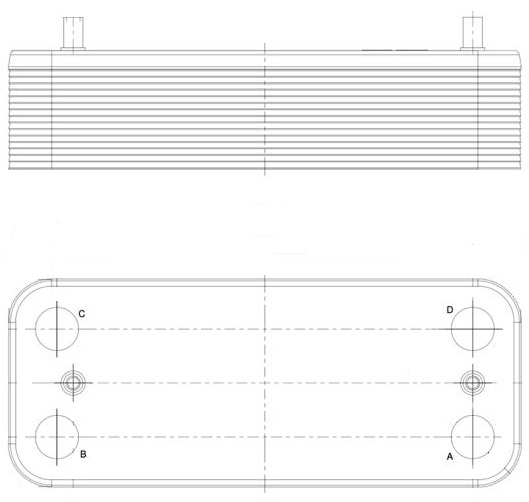

Brazed heat exchangers are essential industrial devices that facilitate heat transfer from one liquid fluid to another or from a liquid to a different gas fluid. Through the brazing process, high heat and braze material are used to keep the heat exchanger plates together, ensuring tightness. They provide a compact, durable, and efficient heat transfer.

Applications

Brazed heat exchangers offer a wide range of applications in various industrial processes. From chemical processes to energy production, food processing plants to HVAC systems, they serve as equipment that provides a solution for heat transfer tasks such as heating, cooling, evaporation, and condensation without requiring maintenance. Our brazed heat exchangers are used in applications such as air conditioning and process coolers, commercial and industrial cooling, regional heating, domestic hot water, heat pumps, fuel cell heaters, oil cooling, hydraulic, motor cooling, air compressors, air dryers, and more.

Advantages

• High Efficiency: Brazed heat exchangers ensure high-efficiency heat transfer through plates with increased thermal efficiency.

• Broad Application Areas: Brazed heat exchangers can be used in various industrial fields, preferred for various applications in sectors such as chemistry, energy, food, and HVAC (Heating, Ventilation, Air Conditioning).

• Durability and Long Life: The brazing process creates a robust structure when assembling heat exchanger components, increasing durability and providing long-lasting performance.

• High Pressure Resistance: Brazed heat exchangers are usually designed with high-pressure resistance, allowing reliable use in various industrial processes.

• Low Maintenance Requirement: Due to their durable structure and strong connections, brazed heat exchangers offer low maintenance requirements.

• Environmentally Friendly: Due to their high efficiency and energy-saving properties, brazed heat exchangers stand out as an environmentally friendly option. They can help reduce carbon footprint by providing energy savings.

Manufacturing and Brazing Materials

Brazed heat exchangers are generally made of heat-resistant materials in a stainless-steel main plate structure. Materials used for the brazing process can be selected according to the process to provide excellent heat transfer and durability, such as copper or nickel braze material.

Design Considerations

In the design of brazed heat exchangers, it is crucial to ensure effective fluid circulation, increase material durability, and optimize heat transfer. Therefore, the careful design and assembly of each component are critical factors that determine the overall performance of the heat exchanger. Brazed heat exchangers, designed to provide superior thermal performance and maximum reliability for any task optimization, are meticulously provided by ERK Proses engineers.

Transferring Heat Efficiently, Use with Confidence!

ERK Proses stands out with expertise in brazed heat exchanger design and manufacturing. With high-quality materials, excellent brazing techniques, and extensive design experience, our company offers reliable and efficient heat exchangers that surpass industry standards.